Electronics Upgrades

An extensive reimagining project that seems to never end, but the final touches are nearing and we hope to finally be satisfied with the layout and equipment we have in place.

Before

After

Before

After

When we purchased Viatori, she had some issues with her electronics package that extended beyond just being outdated. The helm was in disorganized, poorly maintained and in a few instances, dangerous. We decided to pull everything and start from scratch. The first step was to decide on an electronics package. We went with Raymarine because of the AR200 system. At the time is was a game changer for us and no one else anything like it. It will take the AIS data, channel markers, waypoints, points of interest and other data and overlay it onto the video feed. Most everything was plug and play with most difficult set up being the analog digital converter. The only original piece of equipment at this time is the loudhailer, which is still functioning fine.

When we started this project we were hoping for it to be issue free. We were just pulling old wire and running new wire. We found more wiring issues than any vessel should have. There were voids filled with expanding foam to stop leaks that only required mounts to be re-sealed. A four day nightmare of trying to run a data cable from the helm to the auto-pilot in the aft cabin because of the foam. Then having to clean it off the cedar closet panels where is dripped down. Contorting and cursing our way through all the helm wiring until we had removed four (4) contractor bags full of old wiring from old upgrades and additions. The engine alert panels were on the starboard side of the helm for both engines. The manual fire suppression switch was under the steering wheel and many other usability issues. Sitting in the helm seat and going over as many scenarios as we could, we moved switches, changed gauge locations, and decided how we were going to operate the vessel. We stripped the helm and started the design and rebuild for safety, uniformity and usability. King Starboard was chosen for the backing panels after looking at some other options. Back lit acrylic was ruled out for durability reasons. Carbon Fiber was an option, but, cutting it creates an ultra fine dust that can cause breathing and lung problems. Stainless and aluminum would be high maintenance and retain too much heat. King Starboard is cheap, easy to cut and shape. We looked at doing a carbon fiber vinyl wrap on the pieces, but it did not look as good as we hoped and repairing the wrap would be difficult. Using 4mm hex button bolts and vinyl lock nuts improved the look and would make anyone boarding the vessel with a screw driver hoping to make off with a monitor or two would be unable to do so.

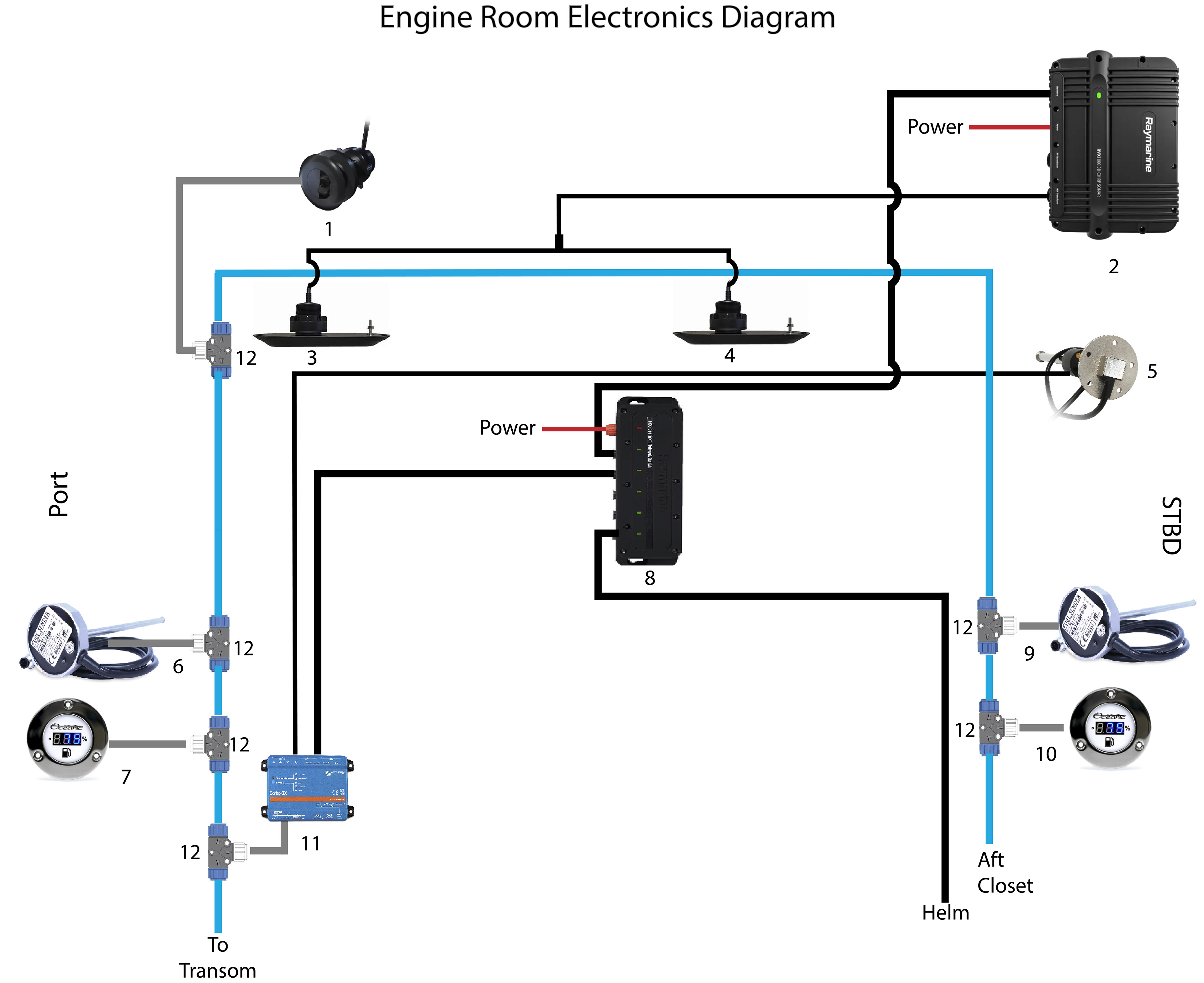

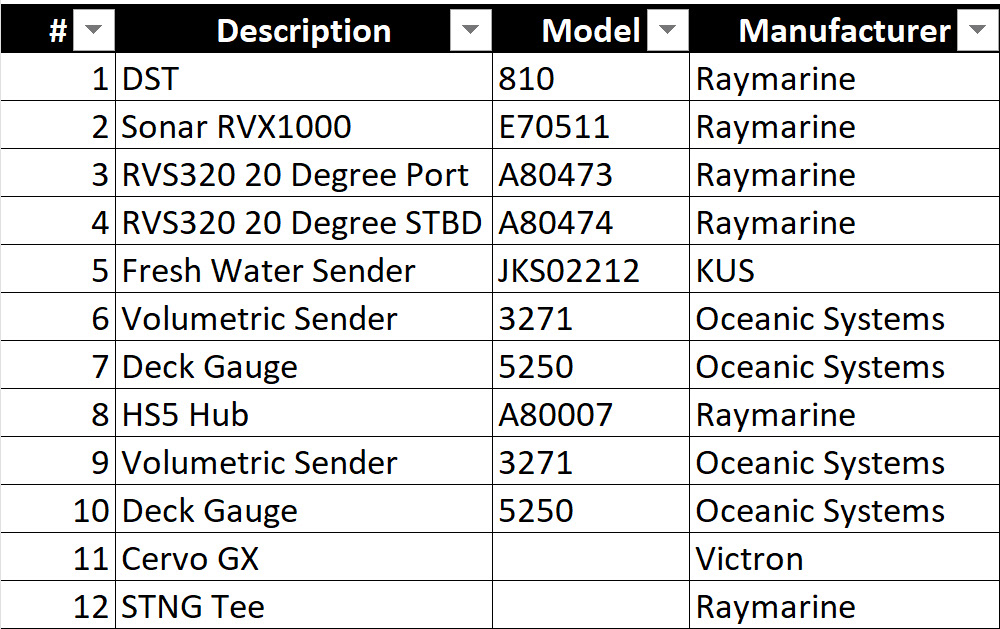

Engine room network

Engine room parts list

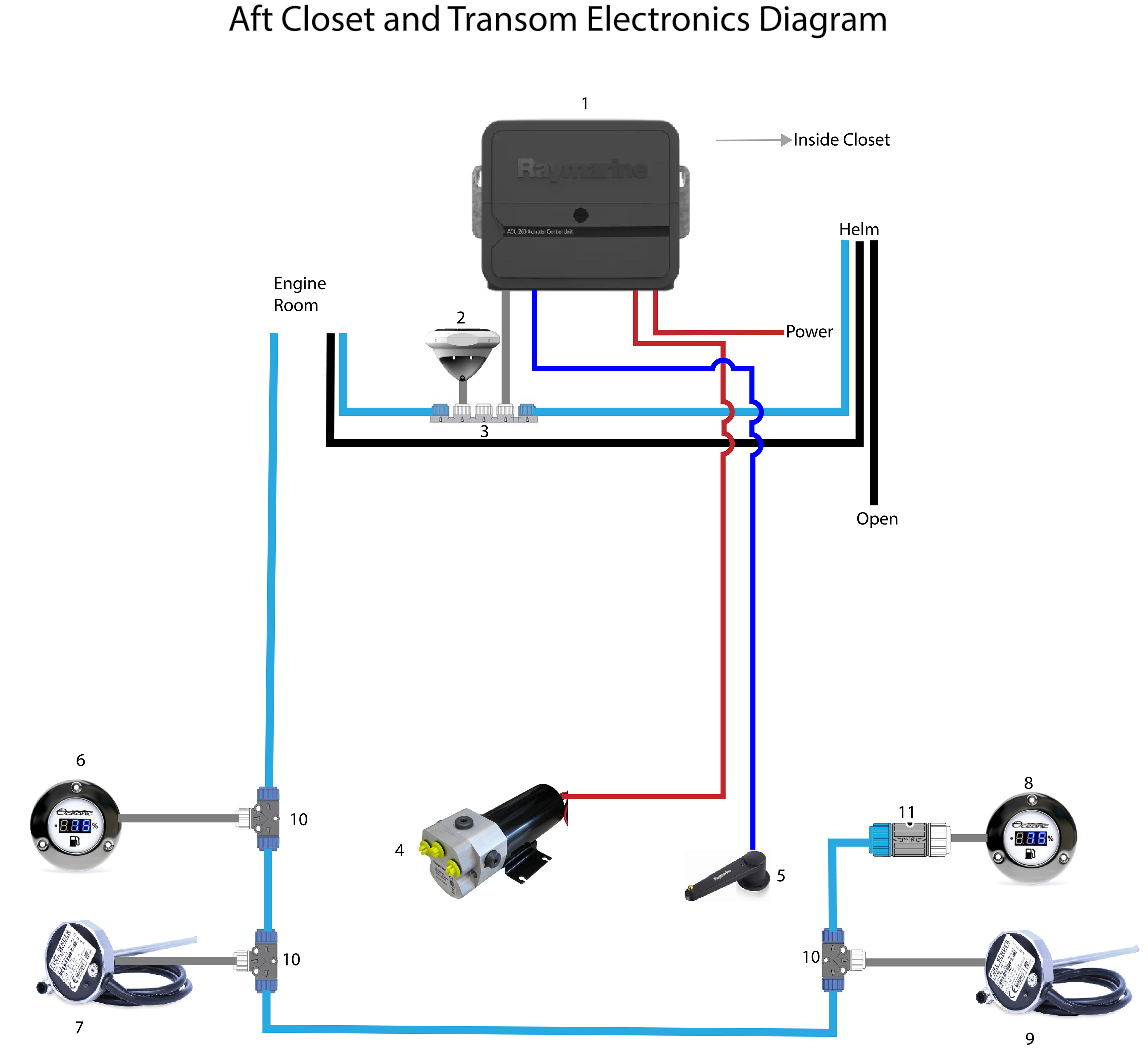

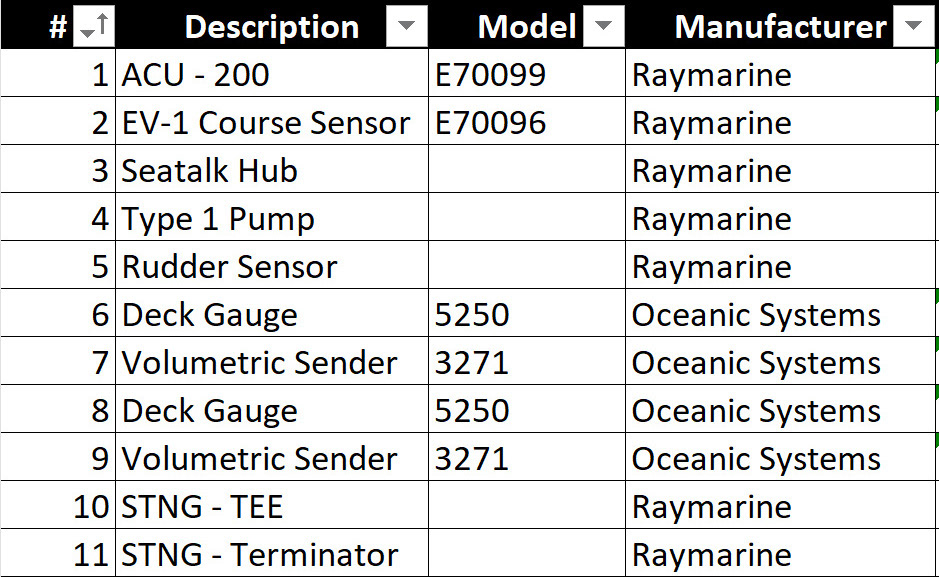

Aft Closet/Transom Network

Aft/transom parts list

One of the last but much needed upgrades were to the fuel senders. The delay in upgrading was do to a few factors, but primarily because we were thinking the access panels needed to be cut to access the tanks. A few months of looking and planning on how to make access panels that would not stand out or be in the way of furniture, we started to move forward. Once our plan was in place, we discovered that the previous owner had just installed carpet over the access hatches. By install, I mean using epoxy to secure the carpet to the subfloor. Cutting a flap in the carpet allowed us to get the much needed upgrade to the fuel senders as four of the three had failed or were sending erratic signals to the gauges.